Frequently referred to as wallboard or by its brand name, Sheetrock, Drywall is not typically cut like wood. Making all the cuts with a saw would generate much dust because it has two paper faces and a gypsum core.

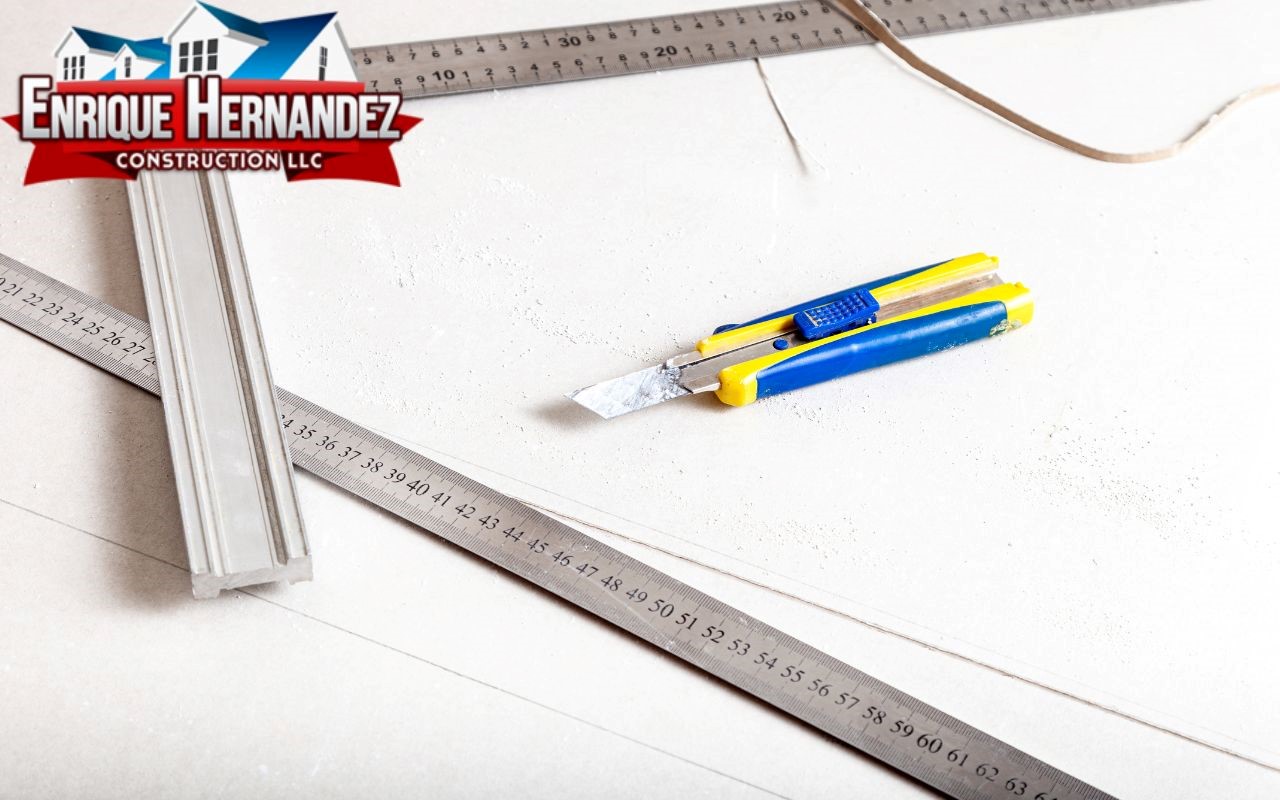

How to Cut with a Simple Knife?

Typically, to cut drywall, a sharp drywall knife is used to score through the paper on the finish side (the side with the white paper).

- When you find the blade dull, flip it over or replace it. Blades cost little. Once that side has been cut, the gypsum core is broken by stretching the drywall away from the cut.

- Make the final cut in the brown paper on the board’s back during the break. Gypsum that has been cut is frequently ragged, but a few passes with a drywall rasp cleans it up nicely.

- Ideally, cutting the drywall is pointless because the gaps will be filled with joint compound if cut about 14 inches too short.

- To ensure accuracy during crosscutting, use a 4-foot drywall square as a reference. Snap a chalk line as a guide and cut along it.

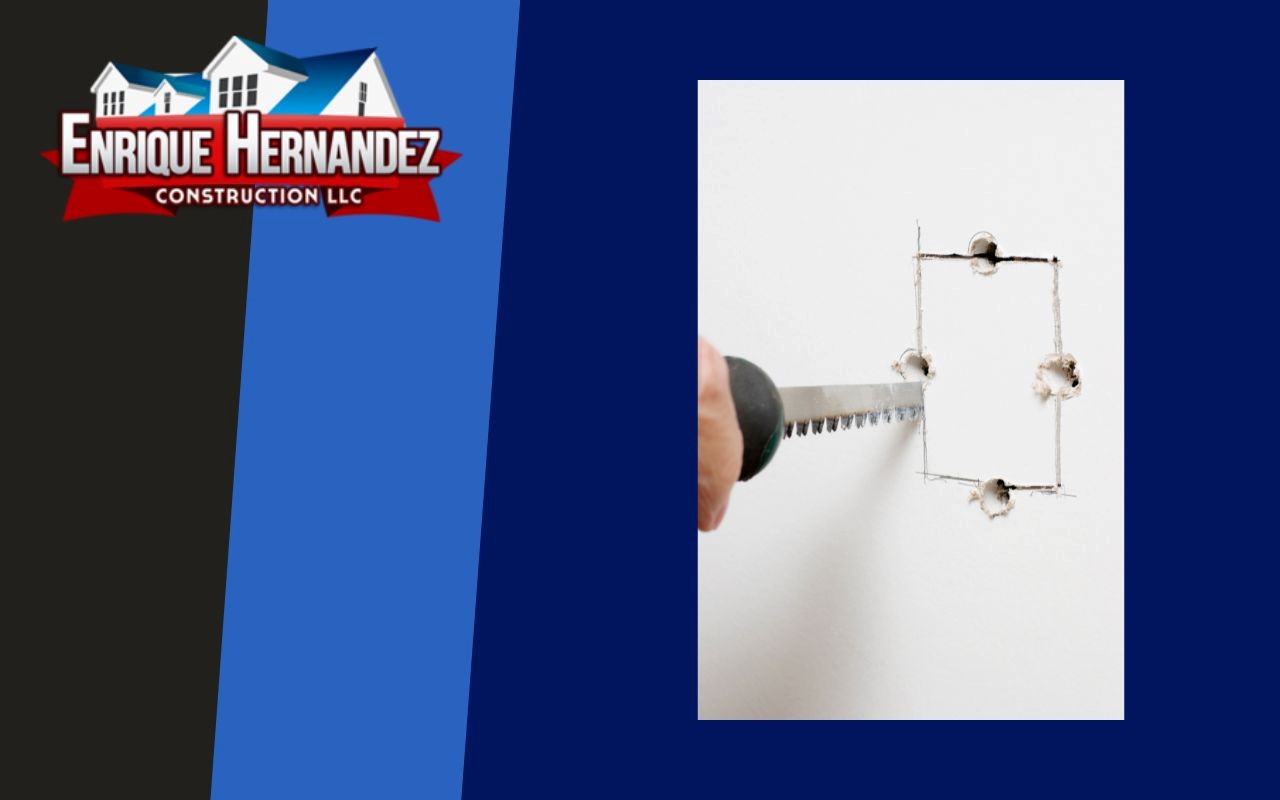

Making Saw Cuts!

You may occasionally need to use a drywall saw. For instance, you’ll need to use a saw to create the two vertical cuts if you need to build an opening for a door.

After that, snap the piece out by joining the ends of those incisions with a conventional knife cut. A wallboard jab or drywall saw that resembles It can use a standard carpenter’s handsaw to make the saw cuts. Choose the jab saw if you only purchase one saw.

Tip: When cutting out door and window openings, hanging the drywall first is the most straightforward and accurate. Guide your saw cuts with the studs on the side of the space and your knife cut with the bottom of the header.

Creating Drywall Cutouts for Electrical Boxes!

You must plan the placement of electrical boxes and rough plumbing carefully.

- Make the incision on the drywall about 1/8 inch larger than the box’s exterior in all dimensions. Even though you can omit it, score the drywall with a knife for the smoothest cut.

- After that, cut along the layout lines by inserting the jab saw through the board’s front.

Accurately layout cutting electrical boxes are more complex than you might imagine. Instead, professionals use a drywall router to make these cuts quickly and precisely.

Using a router, you can also make cuts for windows and doors. The amount is produced clockwise when the interior of the opening directs the router.

The remainder of the screws required to hold the sheet up is driven after the boxes and openings have been cut out.

Quick and easy tips to get a professional finish when cutting drywall

Getting a professional finish cutting drywall can be tricky but rewarding. Here are some quick and easy tips to help you get the job done right:

Start with the right tools.

Having the right tools for the job is essential for getting a professional finish when cutting drywall. Make sure to use sharp blades, such as carbide blades, as these will make it easier to cut accurately and cleanly. Additionally, invest in a good quality measuring tape and square to ensure your measurements are precise and accurate.

Mark your measurements carefully.

It’s essential that you mark your measurements accurately. Hence, you know exactly where you will make each cut before you begin. A great way of doing this is using a pencil or marker instead of an ink pen or permanent marker. This will give you room for any adjustments that need to be made during the process.

Use appropriate techniques when cutting drywall.

For most cuts, it is best to use a sawing motion with a utility knife or putty knife instead of a hacking motion. This will create smoother edges and cleaner lines, resulting in better-looking results.

Cut from both sides of the wall if possible.

When cutting larger pieces of drywall, it’s always best to cut from both sides of the wall if possible, as this helps ensure the edges are even. There are no gaps between them once they have been installed on the wall frame.

Take care of the details.

Take care when removing any excess material from your cuts. If any excess material around your cut lines needs to be removed. Take extra care not to damage either side of the material while doing. This could cause uneven or rough edges, which would adversely affect the overall aesthetics of your finished project.

The good idea is to use sandpaper or a small file to gently remove any excess material without causing damage to your workpiece in the process.

Finish off any rough edges

Once all of your cuts have been made. All excess material has been removed, and you must finish off any remaining rough edges by lightly sanding them down until they are smooth and all around the perimeter of your workpiece.

This can be done using fine-grade sandpaper that won’t damage surrounding areas while providing an adequately smooth surface for the project.

Let us take care of your Drywall needs – Enrique Hernandez Construction LLC.

Drywall cutting is a straightforward operation. Accurately measuring the locations of cutouts for outlets and other objects might take much work. The good news is that drywall mud can conceal practically any flaws, saving you from having to throw away imperfect sheets.

A company such as Enrique Hernandez Construction LLC can assist you if hanging drywall differs from your idea of fun or if you need more time for a big project.

Contact us today for more information on our drywall services